As mentioned previously, I wanted to make the “easy camisole.” This has turned out to be not so easy. None of my gauge swatches were similar to the gauge the pattern requires. The hem is of a type not normally done on the Passap (or maybe just generally not with dual bed machines).

Since none of my gauge swatches even came close to matching what the pattern calls for, I thought I’d just use the fabric I liked best. The pattern provides measurements on a diagram for each section, but these do not seem to add up to the final garment length. With the measurements appearing to be inaccurate, I can’t calculate how many rows I’ll need per section. So entirely choosing my own fabric is out – at least at this point.

Then I decided I’d rework the pattern for a tubular cast on – then I wouldn’t need to do the fold up bit for the hem. At first glance, all I thought I’d need to do was adjust the row counts used in the pattern to account for not doing the hem the same way. Which really is all I need to do, as I looked at this again in order to write an accurate post here, and figured out my row-counting-issues (I think).

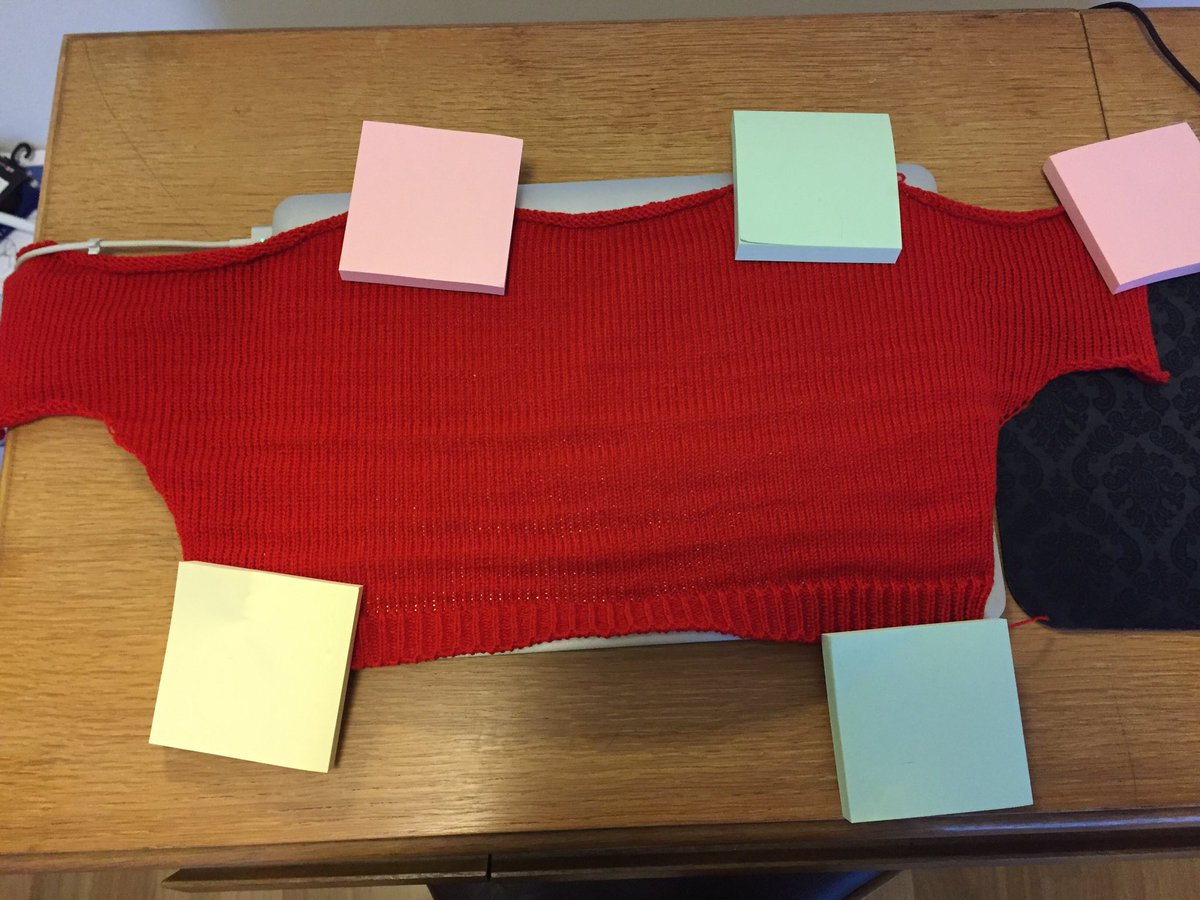

At this point, I was rather frustrated. I reviewed the measurements from my swatches and decided I’d pick the one with the closest match on rows. The width measurements given on the pattern’s diagram look to be correct. I also figured that I might as well attempt the folded up hem used in the pattern. I figured I’d be good from here on out.

No, of course not. It couldn’t be that easy. The single bed cast on with the acrylic waste yarn goes okay (using the lazy/ugly method – every other needle in working position, knit one row, all needles in work, knit one row), but beyond that… not a chance. Stitches are refusing to knit and not just one here or there, but anything from one to twenty in a row. I really can’t figure out what’s going on. Even if I fix the missed stitches in the first row after cast on, it happens again the next row. And the next. And the next. If I can get enough length to use weights, that seems to help, but only for the stitches that are directly weighted. Anything in between the weights, those don’t like to knit (and with 124 stitches cast on, there’s quite a few in between). I have wiped down and oiled the machine, but to no avail.

I’m not sure where to go from here. Maybe since I think I’ve got the row count adjustments for a tubular cast on and hem figured out, I should attempt it that way.

I’m very curious about using waste yarn and ravel cord when doing a tubular cast on. Not quite sure that it works, or if there’s even a case where this makes sense. Will have to think about this some more.